How to use a tire changing machine?

The general steps for using a tire changing machine are as follows:

Preparation

- Inspect the equipment: Make sure that the power supply of the tire changing machine is connected normally, the operating handles and knobs are flexible and reliable, the lubrication parts are well lubricated, and the machine has no obvious hidden dangers of failure.

- Prepare tools: Usually you need to prepare auxiliary tools such as pry bars, tire grease, and air pressure gauges.

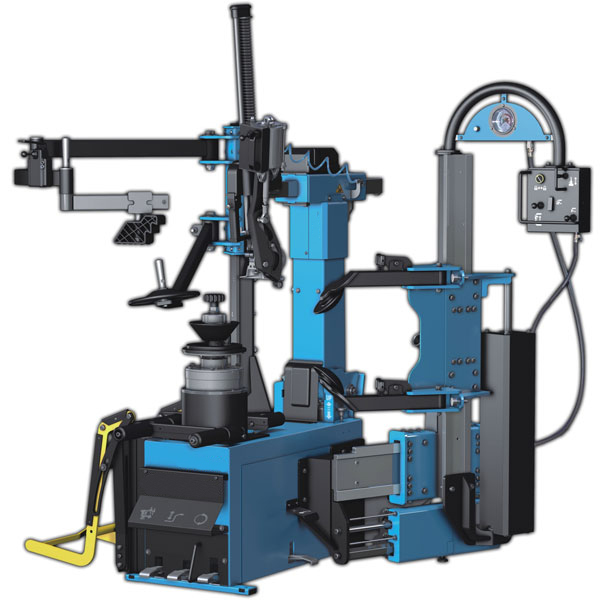

- Fix the tire: Place the tire to be removed flat on the workbench of the tire changing machine, and use the clamping device of the workbench to tightly fix the tire rim to ensure that the tire does not shake or rotate during operation. The clamping methods of different models of tire changing machines may be different, and common ones include manual screw clamping and pneumatic clamping.

Remove the tire

- Remove the valve core: Use a valve core wrench to unscrew the tire valve core, release the air in the tire, and make the tire completely deflated.

- Separate the tire from the rim: Use the separation arm of the tire changing machine, insert the head of the separation arm into the gap between the tire and the rim, and then use the operating handle or button to make the separation arm apply force to separate the tire bead from the rim. Generally, it is necessary to operate evenly around the circumference of the tire so that the entire tire bead is separated from the rim.

- Removing the tire: Insert the tire changing machine's crowbar between the tire and the rim, use the machine's rotation function, and cooperate with the crowbar to pry and slowly remove the tire from the rim. During the removal process, be careful to avoid the crowbar scratching the rim and tire.

Installing the tire

- Cleaning and lubrication: Use a wire brush or rag to clean the debris and rust on the rim surface, and ensure that the rim surface is clean and smooth. Apply an appropriate amount of tire grease on the rim edge and tire bead so that the tire can be installed on the rim smoothly.

- Installing the tire: Put the tire on the rim and align the tire valve hole with the valve hole on the rim. Then insert the tire changing machine's crowbar between the tire and the rim, and use the machine's rotation function to gradually install the tire on the rim. 3.During the installation process, pay attention to the correct installation of the tire direction and pattern.

- Install the valve core and inflate: Install the valve core to the valve stem, and then use the inflation equipment to inflate the tire. Pay attention to controlling the air pressure when inflating, and inflate according to the air pressure value marked on the tire. 43During the inflation process, observe whether the tire is installed in place and whether there is any leakage.

Complete the work

- Check the tire: After the tire is installed, turn the tire by hand to check whether the tire is installed flat and whether there is obvious deflection or shaking. At the same time, check whether the tire pressure meets the standard and whether the valve stem is installed firmly.

- Clean up the work area: Clean up the debris and tools on the workbench, turn off the power of the tire changing machine, and keep the work area clean.

When using the tire changing machine, be sure to strictly follow the operating instructions of the equipment to ensure safety. If you are not familiar with or unsure about the operation, it is recommended to consult a professional or receive relevant training first.