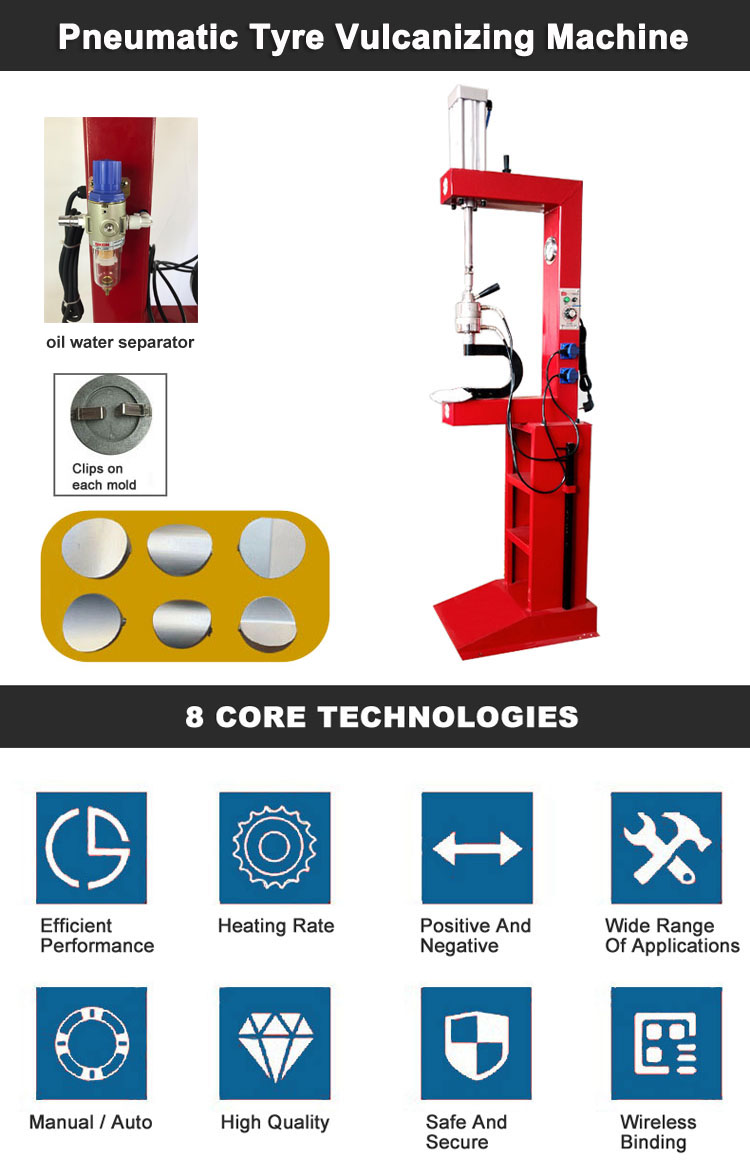

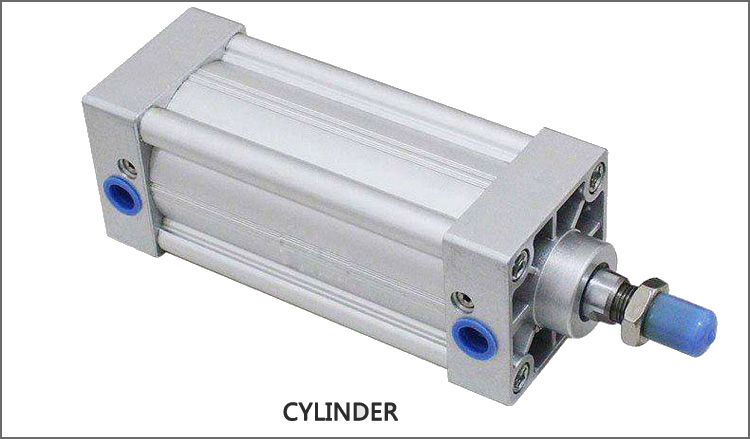

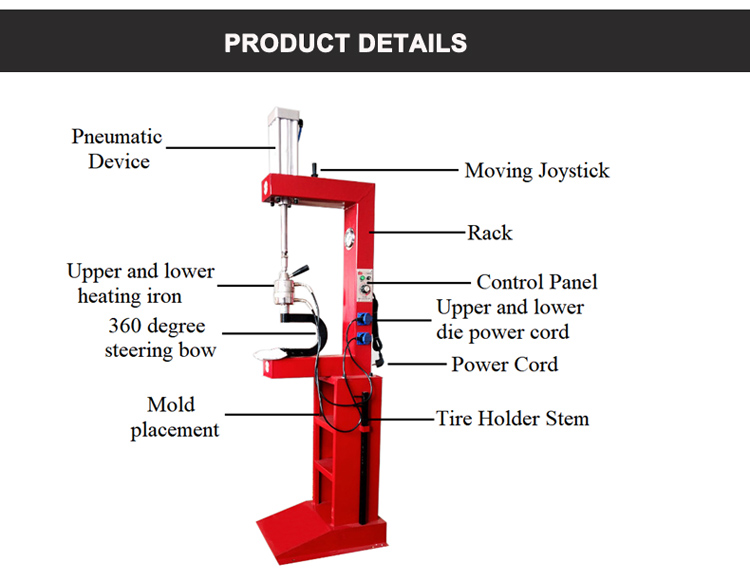

● Pneumatic cylinder with F.R.L connection

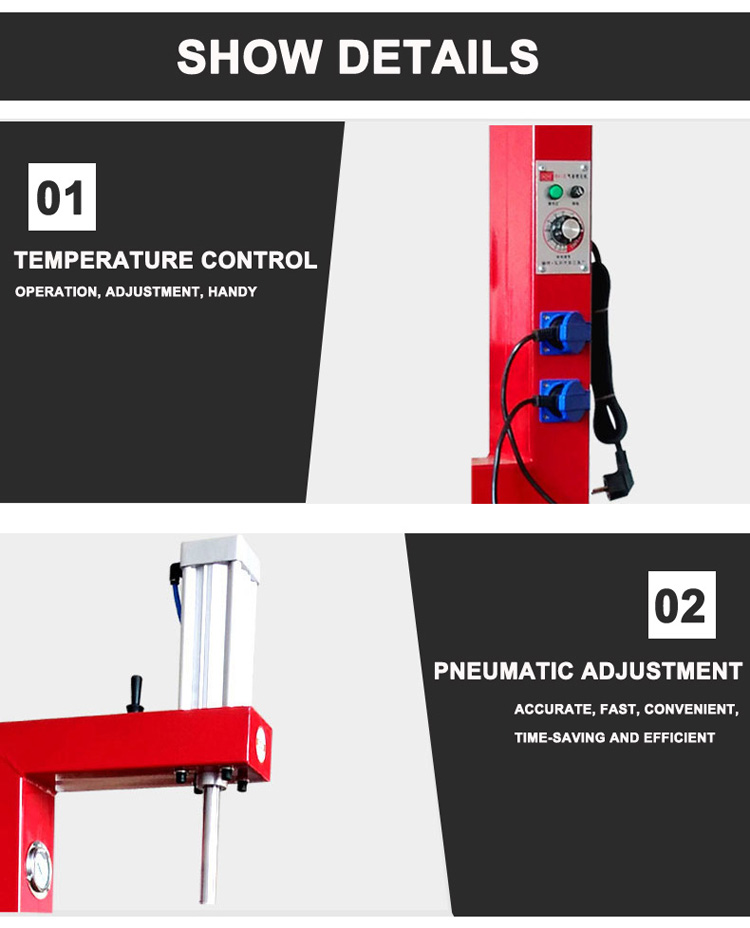

● Signal light , circuit protection , 120 minutes timer

● Upper and down irons can work either separate or together

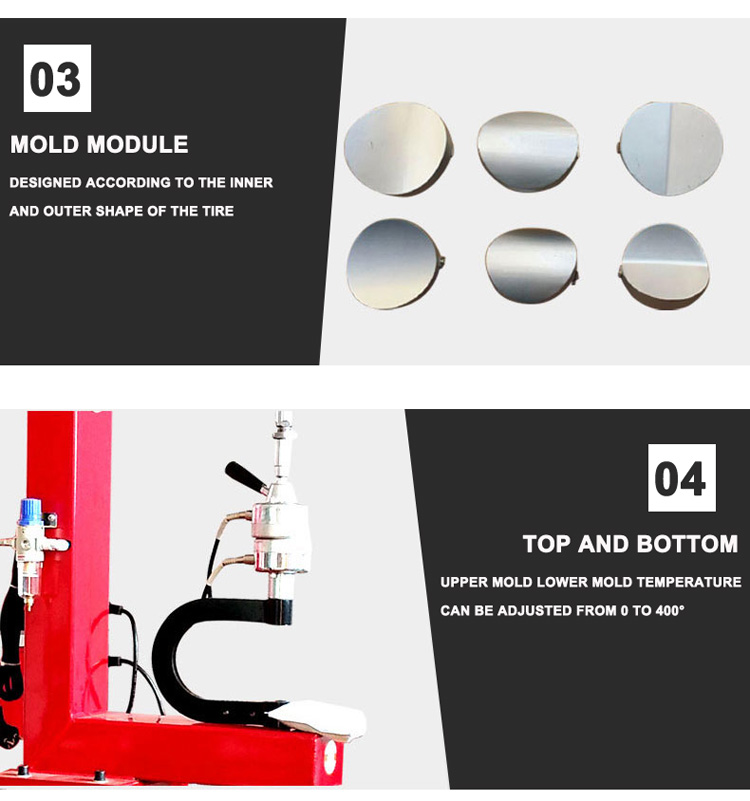

● Eight plates fits repairing requirements of tire crown , tire shoulder and tire sidewall

● Applicable for inner tubes, passenger tire, truck tire and vacuum tire .

Tire Repair Methods

1. Clear surface of the wound which is going to be repaired on the wheel And make a mark .

2. Roughen surface of the wound with sander . The roughened area shall be rather larger than the wound. Internal side of the wound shall also be roughened if the wounded area is larger than normal to make the wound penetrated, and steel wire shall be cut off if the wire is exposed.

3. Hot setting glue shall be smeared uniformly on the roughened area.

4. Make a piece of raw rubber with appropriate size and paste it on the wound . Raw rubber can be applied with cord or applied on both sides if the wounded area is larger than normal . (Note: when raw rubber is applied on both sides , the rubber shall fill the wounded area without air)

5. Choose the suitable mould for the wound and press on pasted raw rubber with mould . Connect the machine with power supply and connect the air compressor to the oil water separator of vulcanizing machine . Put the mould with repairing tyre on the heating iron of vulcanizing machine . Open the switch of air cylinder .Then the raw rubber will be compacted.

6. Open the timing temperature control switch. And start heating according to the thickness of raw rubber ( Note: 4mm thickness raw rubber can be vulcanized in every 10 minutes ).

7. The power supply will be cut off when the set repair timing comes, which indicates that the repair is finished . But it is not allowed to loose the air cylinder and take off the tire at this stage . It is required to take the tire off machine after the temperature of tire is cooled for a while .