Tire Changer S-T598

Tire Changer S-T598

TECHNICAL DATA

| Rim Diamter | 14" - 42" |

| Max.wheel weight | 1600kg |

| Max Wheel Width | 1050mm |

| Max Tyre Diameter | 2300mm |

| Hydraulic Pump Motor | 2.2KW 380V - 3PH - 50HZ(220V Optional) |

| Gearbox Motor | 2.2KW 380V - 3PH - 50HZ(220V Optional) |

| Bead Breaker Force | 3300kg |

| Max.Torque | 5265N.m |

| Operation Control Voltage | 24V |

| Machine Weight Approx | 758kg |

| Overall Dimensions Approx | 2500×2000mm |

| Power | 220/400V 50/60HZ 1P/3P Optional |

| Noise Level | ≤70db |

| Temperature | 0℃~40℃ |

PRODUCTS INTRODUCTION

· Semi-Automatic universal truck tire changer S-T598 for industrial,agricultural and earthmoving wheels

· Rim capacity 14”- 42”

· Italian pump

Product Features:

Engineering Tire Stripping Tire machine, is a of the large-scale tire machinery. Can be grilled passenger cars, trucks, agricultural vehicles. Industrial car tires. Hydraulic system, the only one People's Congress tire perfect disassembly, labor intensity low, high efficiency. Movable low voltage control handle. The operating voltage is stable and safe.

1. Deep groove rims for passenger cars, trucks, agricultural vehicles and industrial vehicles, and disassembly of vacuum tires and pressure-ring tires.

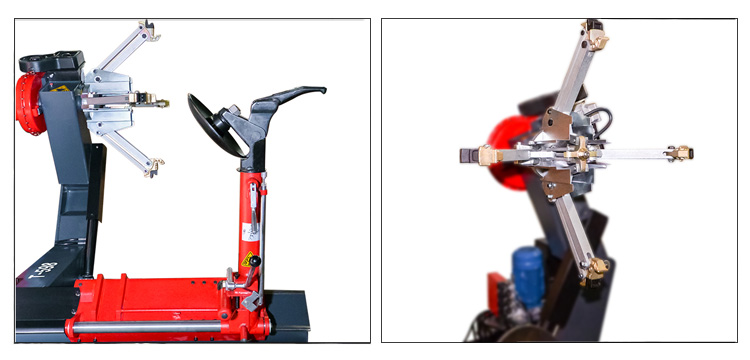

2. Automatic Take-off and landing of the tire arm and moving before and after.

3. The tyre removal tool can be rotated and the disc mandrel on the tool head is designed with rolling bearing. Even in the operation of the tire mouth resistance is large, can also rotate freely.

4. Equipped with hydraulic drive plate, the tire in the disassembly and removal machine left and right without manpower.

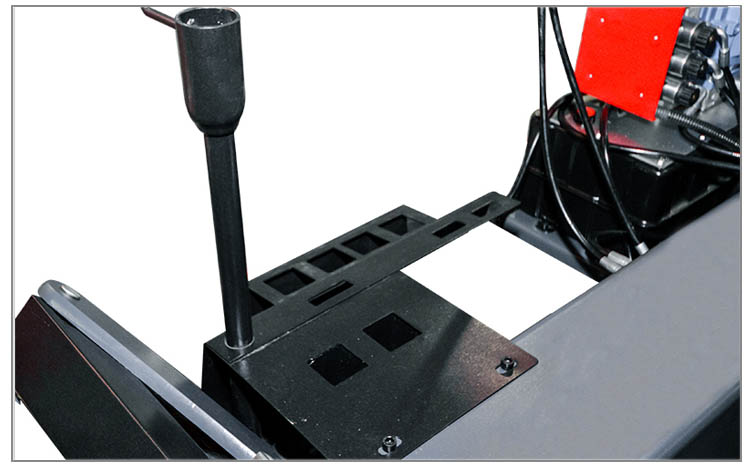

5. Lightweight, portable console to facilitate the operation of various angles to observe in order to prevent misoperation.

6. Two-speed spindle motor to improve the efficiency of the demolition.

7. The lifting arm oil cylinder is the center support, has the safety protection switch.

1. Prepare well for lubrication before stripping.

2, before the tire to confirm the voltage is not the machine voltage.

3. The steel rim is fixed before the tire is grilled.

Demolition of a Bead tire

1. Move the tires to the four-claw universal fixture.

2. Mobilize the good machine, let the four claw universal fixture to fasten the tire wheel.

3. Apply the lubricating oil, move the assembly arm to the side of the tire layering with the assembly plate to the tyre and rotate to completely disengage the tire mouth from the steel rim.

4. Use the layering device to draw the layering, and use the assembling plate to rotate the strip.

5. Move the assembly arm to the side of the tyre, and rotate the side of the tyre to move the assembly plate outward, and protect the valve from the outside.

Layering tyre installation.

1. The tyre is loaded on the steel rim by hand.

2. Move the assembly arm to the outside of the tyre and tighten the tyre with the assembly plate.

3. Use the assembling plate to install the steel rims.

Common:

1. If you accidentally make a small mouth, you can use the broken place figure butter.

2. Pick Tire machine tires side scrape a piece, first of all to pick the tire machine bird Head adjustment good, tire installed with professional liquid to the tire lip coating evenly.

3. The tyres are easy to slide out when the tyres are loaded, and the place where the initial pressure goes down must always be pressed and pressed to the deepest groove.

4. Grilled tire machine Easy to pick bad tires of the fetal lip, the general problem is inadequate lubrication.